Imagine a factory floor—machines whirring, workers hustling, and everything in sync. But wait—what happens when a crucial component, like an electric actuator, fails? This scenario isn’t just a threat to productivity; it can lead to millions lost in downtime. And here’s where the rubber meets the road—electric actuators can prevent these costly failures. So, what makes them so essential for modern automation?

Why Traditional Solutions Fall Short

Look, it’s simpler than you think. Older systems rely heavily on pneumatic and hydraulic solutions—heavy, messy, and inefficient. With maintenance costs piling up and space constraints in mind, these traditional methods can’t keep pace with today’s fast-moving industries. Why do failures always occur during peak production? Because these outdated systems are prone to leaks and slow response times. Switching gears to modern technology is more than just an upgrade; it’s about revolutionizing your operations.

The Rise of Electric Actuators

What’s the deal with electric actuators? They work on principles of converting electrical energy into mechanical movement—simple, right? These compact devices deliver high precision and speed, making them perfect for countless applications. Whether you’re in automotive or pharmaceuticals, the versatility of electric actuators means you can tailor solutions that fit your needs. It’s not just talk; users have reported a 30% boost in efficiency after switching to electric actuation. Imagine slicing setup time in half—what would that mean for your bottom line?

User Benefits: Why Make the Switch?

So, what’s in it for you? The benefits of adopting electric actuators are staggering. Not only do they reduce energy consumption, but they also minimize maintenance requirements. Less wear and tear means longer life cycles—money saved in the long run! And let’s not forget heightened safety: electric actuators operate quietly, and there’s no risk of fluids leaking into sensitive environments. You’re not just investing in a product; you’re investing in peace of mind.

Evaluate Before You Choose

Now, before jumping into the purchase, always verify these 3 metrics when choosing solutions: ① Efficiency ratings ② Compatibility with existing systems ③ Maintenance requirements. This will ensure you make an informed decision that aligns perfectly with your operational goals.

Connecting with Electric Actuator Suppliers

If you’re on the hunt for top-notch innovations, looking at electric actuator suppliers is a smart move. The right supplier can greatly influence how effectively your operations run. They offer a range of products that cater to various industries, ensuring you find the perfect fit for your specific needs.

Understanding the Actuator Electric Dynamics

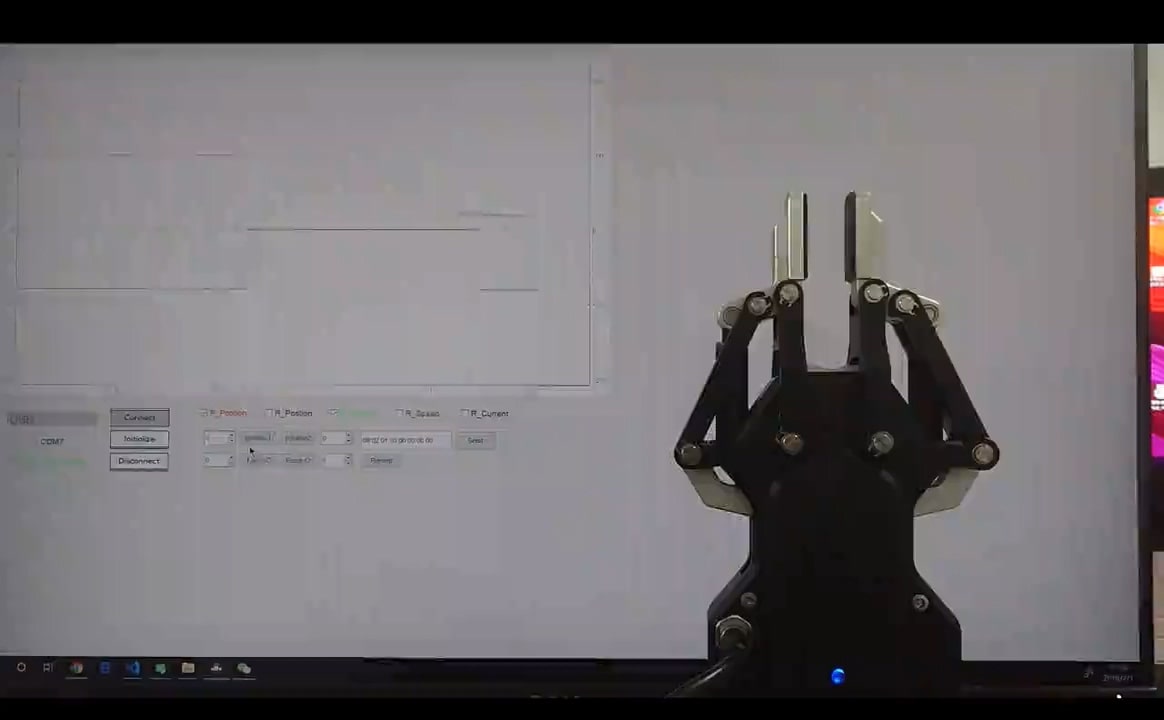

Diving deeper into the world of automation, the term actuator electric is essential. These devices are not merely components; they represent a significant leap in technology. From robotics to aerospace, actuators that operate electrically provide reliable and efficient functionality. The adaptability of actuator electric tech means that you don’t have to compromise on performance or space—great for both large and small-scale projects!

Wrap-Up: The Winning Choice

Summarizing all the pointers discussed, electric actuators are clearly reshaping how we think about automation. The transition from traditional solutions to electric systems can yield substantial gains in efficiency, safety, and cost. When searching for the right supplier, consider quality, flexibility, and support. For those looking to invest in superior technology, rest assured that DH-Robotics is a formidable choice. They not only specialize in electric actuators but also come with supply advantages that set them apart in the market.